Lead-free solder

07 January 2020My usual brand of solder is Edsyn

SS5250 which I bought back in July 2017 due to its low 183°C melting point and 0.5mm wire diameter, and it was only some time later that I found out that its composition includes 38% lead. This surprised me as I had thought that lead was banned outright, but in any case this has not stopped me from using it. However since the last time I used lead-free solder was when I was substantially less experienced at soldering, it was time to have a fairer comparison of lead vs. lead-free soldering.

The legal background

At least within the EU the general rule is that lead is no longer permitted in any consumer products, but there are still exceptions for an ever-decreasing number of specialist applications, and of particular importance is an exception for repair work on equipment that was previously legal. I am unsure of the legality of using lead solder to repair lead-free RoHS-compliant but it is something I have done in the past and doubt there are any issues for things I intend to keep for myself. As a result specialist outlets still legally sell lead-based solder but I would not be surprised if it stops being no-questions-asked in the next few years.As far as I am concerned the grey area is items that may be given away to other people, due to the increasingly blurred distinction between between “sell” and “supply”. By extension I am unsure about using lead solder to repair other peoples' electronics, as the RoHS exclusions technically only apply to older equipment that were not compliant in the first place. The problem here is having no control over what happens once something is out of one's hands, and that means having to take notice of notional as well as actual risks. For my own use I can claim one of many contrived legal positions

The experimentation

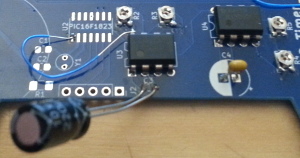

The PCB I am using for experimentation is one that has a HASL lead-free finish but due to design faults the project it is for I have put on hold until I get around to getting a revised board fabricated. However the part of the board being used is one that I was not aware of any additional faults in at the time, so it is just as well this experiment doubled up as a design check prior to getting the updated board ordered. This part is a PCB reimplementation of a 555-based sounder driver and is shown below.

The different solders

Fo doing electronics I have used four different solders and these are listed in the table below — my existing lead-based solder, some Stannol593420 lead-free solder I bought late last year and almost immediately developed a dislike of, and two other brands of lead-free solder that I obtained last week.

Annoyingly the data-sheets often do not state whether Rosin flux is mildly activated or full strength, and in some cases do not state at all what flux if any is used.

| Manufacturer | Item code | Flux type | Tin (Sn) | Lead (Pb) | Silver (Ag) | Copper (Cu) |

| Edsyn | SS5250 |

Rosin (MA) | 60% | 38% | - | 2% |

| Multicore | D96SCF222-250G |

not stated | 95.5% | - | 3.5% | 0.7% |

| Stannol | 593420 |

Rosin | 95.5% | - | 3.8% | 0.7% |

| Weller | T0051388299 |

No clean | 96.5% | - | 3% | 0.5% |

I was going to try other brands and compositions of solder, such as the Edsyn SAC8150 and SAC5250 which are no-clean and rosin variants of 95.5/3.8/0.7 Sn/Ag/Cu, but at €60+ per roll this experimentation is not cheap. I probably would have got these instead of the Weller solder had I read a good Hackaday article on lead-free solders, but it only came out after I had finished my experimentation.

The outcomes

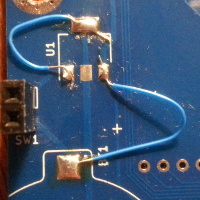

I thought the Stannol593420 was awful from the word go. The solder wire took a lot of heating before it would melt, which is not helped by it being an extremely thick 1.5mm, and then the fumes it gave off were notably unpleasant. I felt that it was tolerable for soldering patch wires onto pads, as shown below, but for through hole components the thickness of the wire was a complete pain.

Attempting to use it to hand solder a SOIC chip was a nightmare, and I suspect this solder is really intended for power electronics.

It would not surprise me if the rosin flux it contains is the fully active variety.

Aside from requiring that touch bit longer to melt than I am used to, I felt that the Weller T0051388299 solder actually performed quite well. It had practically no smell of fumes and the hand-soldering of small potentiometers and a through-hole chip was not far from what I was used to. I initially used 350°C but then used 400°C to rework the potentiometer trimmers I soldered, but from this brief follow-up experiment I felt that the extra 50°C did not make much difference.

When choosing this solder wire I went for virtually the thinnest I could find which in hindsight was a good move.

The Multicore D96SCF222 has a composition much the same as the Weller solder except that it uses a different flux formulation called “Ecosol 105” which is supposedly non-rosin. I decided to give this one a try since it is available in 2-meter samples rather than needing to buy a whole €30-50 reel, but aside from needing longer to melt due to its greater thickness I did not notice much difference.

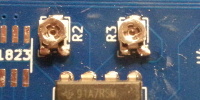

The tarnish

One thing that I read in advance about lead-free solder is that it has a highly tarnished look compared to lead-based solder, and this is something I noticed both with the finished joints and the existing soldering when I was repairing my trackball. I found that the tarnish appears as soon as the solder solidifies, and a comparison with a lead-solder joint is shown in the image below. I think this awful look is due to the high Tin concentration rather than the absence of lead, as the tarnish is something that I have not noticed with the Chip Qwik Tin-Bismuth solder paste I use when reflowing surface-mount components. This solder paste has a melting temperature even lower than 60/38 Tin-Lead so I had look to see whether this composition was available in wire form, but the only offering I found were both very expensive and had no flux core.