Prototyping boards

24 January 2021Because of my tendency of not wanting to dismantle circuits I have tended to dislike solder-less breadboard, and as a result over the last 3-4 years I have used a variety of prototyping breadboards, remarking on them as I went along. As part of a stock-take and general reordering of my stores I came across quite a few stashes of boards I thought I had used up, in cases because I felt alternatives were better, and as a result felt it was time to compile all my thoughts on the different types into one place.

Stripboard

Strip-board gets its name due to having whole lines of holes connected together in strips, and the brand I have almost always used was Kemo ElectronicE012 boards that are 10x10cm.

In most cases such as when using integrated circuit chips with this type of board, some of the tracks will need to be cut and there are special tools available for doing this.

This type of prototyping board works well in circuit designs that have some form of parallel buses, which is what my many LED-based displays made use of, most notably my iconic 17-segment display.

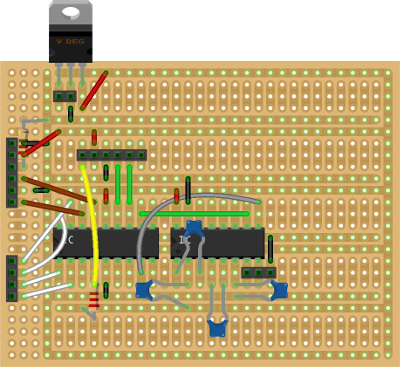

Working out which tracks need cutting and where involves a significant amount of up-front planning, which I have often done using Fritzing.

I used stripboard quite a lot in my early days back in 2017 but since then it has fallen out of favour because it is rather labour-intensive — in particular a lot of care needs to be taken when doing the actual track cutting to make sure there is not a thin strip of remaining copper making contact across the cut. The need to plan out the track cuts also makes the board unsuitable for circuits designed on-the-fly.

Perfboard

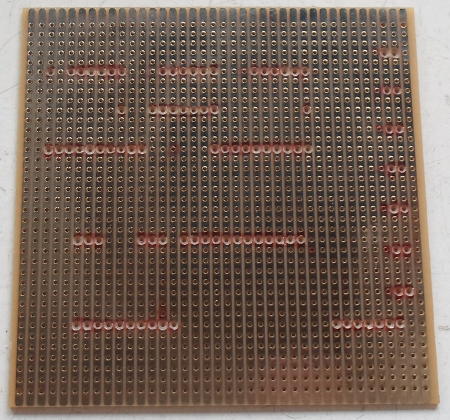

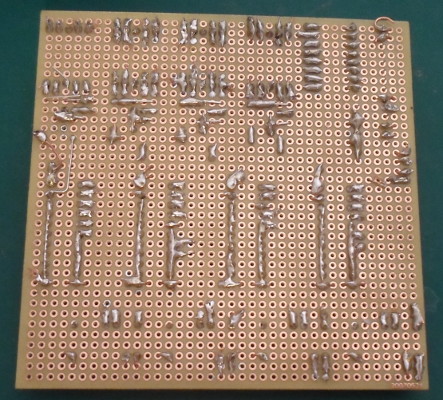

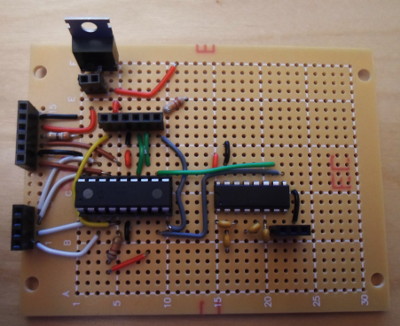

Perfboard does not have any of the individual holes connected together so solder bridges need to be made between adjacent holes. Quite often this is done by bending over component leads to make a connection on the underside of the board and then soldering them in place, as can be seen in the picture below which is of 10x10cm MulticompMC001796.

It is a bit of a pain to use with integrated circuits due to the need to carefully wrap wires around the chip legs, but the trade-off is flexibility especially for circuits that have a high proportion of discrete components — in particular I have found perfboard quite good for circuits that are built on-the-fly rather than planned.

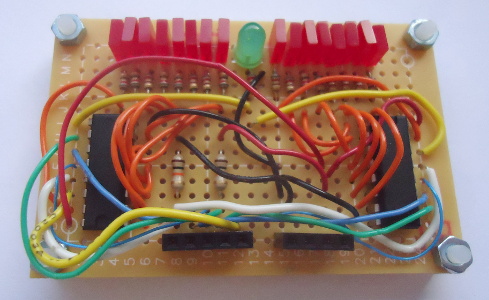

I have often used Multicomp MC01006 for things like break-out boards and some single-chip circuits but since then have preferred to stock the slightly larger MC01007 which was used in the circuit shown below.

My finding is the latter to be just the right size for the type of circuit that would be built in a day or two, with four of the seven prototyping boards I used in 2020 being the size.

A few days ago I sourced the bigger still MC01008 which is the same size as the IC chip board mentioned later but I have yet to try it.

Integrated circuit board

The MulticompMC01010 is my favourite prototyping board, having been used for more of my published circuit projects than any other, my only complaint being that the top-side does not have lines indicating which holes are joined together.

It is clearly designed for use with integrated circuits but the close proximity of power tracks also makes it convenient for building circuits with lots of discrete transistors, and I quite like having the mounting holes as these days I often put the board onto spacers so that the solder side does not lie directly on table surface.

At roughly 7cm by 9cm it feels a good size, unlike the 10x10cm stripboard and perfboard which feel that bit too big.

Hybrid board

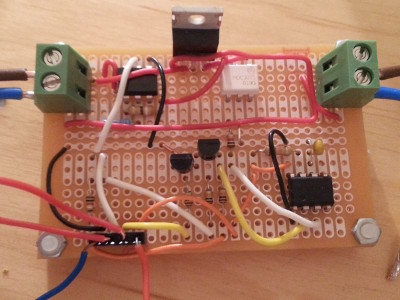

Also from Multicomp is theMC01009, which I only came across a few months ago, although this layout is also known as Radio Shack 276-150.

It seems to be an attempt to make a cross between perfboard and integrated circuit board which is at the very least an interesting idea, and the hard-wired triac control was intended to see how well it worked in practice.

Overall my impression is good although the way I had to split the circuit over two boards was a bit of a pain.

I also came across the similar MCM 21-4541 which is shown below but so far have yet to have the opportunity to try out.

My overall impression is that it is a bit better for integrated circuits, particularly in the way it sacrifices the extra row of holes compared to the MC01009 in order to make it symmetrical.

Although less flexible I suspect that having triplets of holes joined together rather than areas of perfboard holes will be more convenient for my use-cases; the down-side is that Fritzing would not faithfully be able to create this track layout.

Busboard

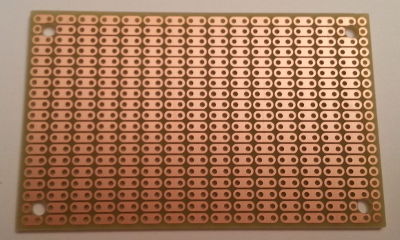

I recently came across the BusBoard brand of perfboards which groups holes into pairs, the idea seeming top be having the flexibility of perfboard but without the pain of wrapping wires around integrated circuit chip legs, and I ordered in some of thePR2H1 variant shown below.

Instinctively I would have preferred it if the direction of the strips was parallel to the short edge rather than the long edge, but before I try it I am not sure which direction is best in practice.

It is also a bit expensive compared to other boards of the same dimensions £2.85 plus VAT each compared to 92¢ I paid for my last batch of MC01007.

Remarks

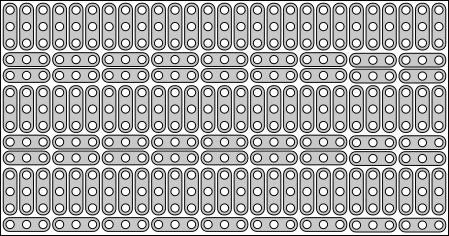

What I would really like is something like the BusBoard but where the holes are in triplets and where some of the triplets are perpendicular, as shown in the mock-up below — I have recollections of seeing boards like this, but I have yet to find a vendor for such a board, and some of the ones that come close are a bit expensive. In practice the MCM21-4541 is probably the closest to this that is readily available and for a reasonable price.

In the mean-time I suspect most of my future projects will use either the Multicomp MC01010 or the MC01007, the choice being down to whether the circuit consists of chips or discrete components.